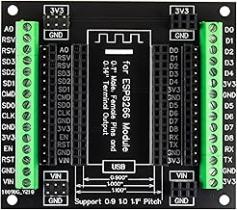

6-pack esp8266 v3 esp-12e,aideepen 30pin nodemcu esp8266 v3 esp-12e development board wlan module ch-340 for

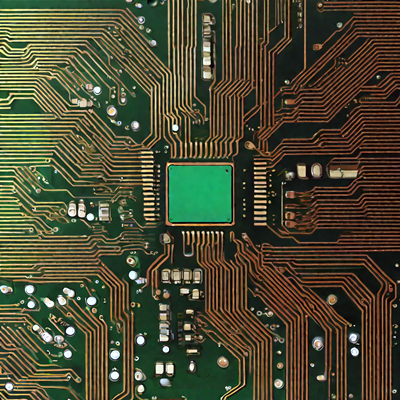

Printed circuit boards (PCBs), commonly referred to as circuit boards, serve an indispensable role linking and securing electronic components while efficiently routing signals and power to enable functional systems and innovative devices. These engineered boards provide the specialized conductive canvases where sketches transform into reality.

Methodically laminated with conductive copper traces in specific patterns across nonconductive substrates, circuit boards replace tedious wired connections between individual components. Component pins instead secure directly into boards during assembly for clean, consolidated pathways distilling complex circuit designs.

While appearing simple as thin sheets housing components, circuit boards requirements demand tightly engineered balances of rigidity, heat resistance, dielectric insulation and more to preserve signal clarity essential for complex electronics and logic gates.

Board substrates consist of layers of densely pressed fiberglass bonded with heat-resistant epoxy resins to provide firm structural foundations across product lifetimes without warping. Dielectric base materials separate embedded copper channels, preventing short circuiting while minimizing crosstalk interference.

Likewise, trace dimensions also factor significantly into signal delivery. Wider traces and increased copper thicknesses bolster currents for power circuits while narrow precision pathways avoid distorting delicate data signals. Ground planes provide referential shields against electromagnetic interference as well.

Modern circuit boards production leverages specialized design software suites paired with automated fabrication and assembly processes for efficiently translating concepts into optimized boards:

Board layouts first draft within computer-aided design (CAD) software specifying component footprints/pinouts, conductive trace routing, layer stacking, production clearances and more based on final product engineering needs. Designers iteratively refine board files through thermal/vibration/fatigue modeling until meeting all electrical and mechanical specifications.

Fabrication specialists transfer board layout files onto dielectric substrate sheets then utilize photolithographic processes to selectively etch away copper laminate material not designated for conductive traces or contact points. Boards undergo finishes like immersion plating to coat traces resisting corrosion over decades.

By means of manually inserted or automated pick and place machines, electrical components are securely soldered to circuit boards, with threaded leads inserted into plated through holes or flush onto surface pads. Precision equipment accurately guides components into layout positions despite microscopically small spacings.

Following assembly, testing examines fabricated boards across key performance indicators like connectivity, durability, temperature response and more. Assembled units undergo environmental stress testing through shaking, thermal cycles and voltage extremes ensuring real-world viability. Design revisions iterate until devices perform ideally.

While universally providing the electrical backbone routing signals, modern circuit boards adapt across specialized types engineered towards meeting unique mechanical and operational demands of different industries and products:

From smartphones to appliances, consumer electronics leverage multilayer rigid boards for densely integrating ICs alongside discrete transistors, sensors and passive support components enabling accessible electronics through mass production.

Mission-critical vehicular systems endure temperature swings, vibrations and electrical noise perturbations through durable boards boasting chopped fiber and woven glass fabric reinforcements for dimensional stability across expected automotive lifecycles.

Aviation and space applications require exceptionally reliable circuit boards rated for extreme thermal gradients from cryogenic to blistering conditions while integrating fault redundancies ensuring fail-safe emergency operation.

Life-dependent medical devices demand the highest-grade boards meeting stringent reporting regulations and change control versioning through extensive testing validation at each iteration as systems advancement necessarily lags behind immediate patient needs.

Across countless applications, reliable printed circuit boards continue enabling exponential technological innovation by providing the specialized conductive pathways supporting everything from daily household conveniences to humanity's most ambitious devices pushing extremes. Their manufacturability facilitates scalability distilling imagination into engineered reality through circuits.

6-pack esp8266 v3 esp-12e,aideepen 30pin nodemcu esp8266 v3 esp-12e development board wlan module ch-340 for

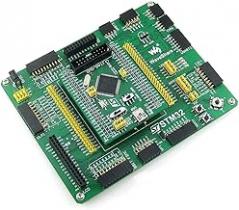

viewtool ficus stm32f407+usb3300 (high speed 480mbps) development boardonly 1 left in stock - order

3pcs esp8266 esp-12e development board wifi wlan wireless module cp2102 for nodemcu for esp-12e for

3pcs esp8266 esp-12e cp2102 nodemcu lua wireless module development board for arduino ide/micropythonfree delivery for

luatos usb c stm32 compatible devpmetment board with air32f103c8t6 mcu, 216mb main frequency, 96kb ram

stm32f4 discovery stm32f407 cortex-m4 development board module st-link v2 swd connector 3v/5v micro-ab usb

for esp8266 super breakout board 3.5mm / 0.14" terminal gpio 1 into 3 expansion board

hiletgo 1pc esp8266 nodemcu cp2102 esp-12e development board open source serial module works great for

asus - rog strix z690-e gaming wifi socket lga 1700 usb 3.2 intel motherboard

ASUS - TUF GAMING Z790-PLUS WIFI D4 (Socket LGA 1700) USB 3.2 Intel ATX Gaming